Fraunhofer IVV works on fast monitoring and adjustment of heat-seal temperatures

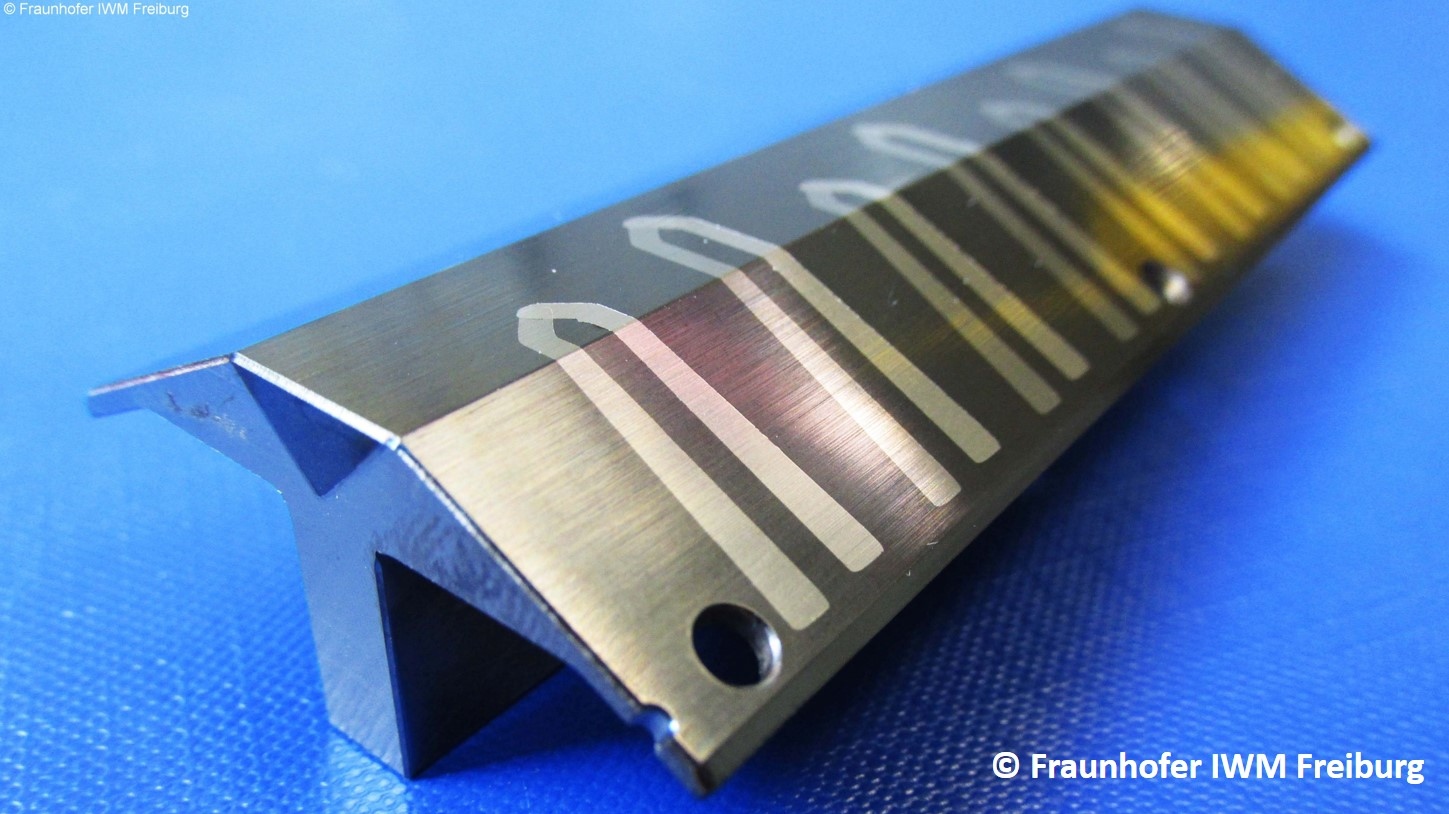

After an earlier project showed that the thin-film-based measuring technology is effective, RobInPro will work towards: increasing the lifetime of the multilayer coating on the heat-seal jaw, potentially through the use of new material combinations; improving the detection sensitivity of the sensors; improving the non-stick characteristics of the tool surface; and readying the sensor system for industrial applications.In the future, these integrated temperature sensors with short response times and high sensitivity could check the heat-sealing parameters, simultaneously at different points, for every seam, reliably reject seals which are out of specification and adjust process parameters, nearly in real-time.

“The thin-film based sensor technology could also be very useful in other areas of plastics processing, such as thermoforming, hot-stamping and extrusion,” says project manager Ralph Jänchen. “Here, temperature sensors close to the surface can help to ensure reliable forming and high surface quality in these applications. Furthermore, the protective and non-stick coatings, which should be developed in the project, will also be usable for classic sealing and forming tools without sensors.”

“The thin-film based sensor technology could also be very useful in other areas of plastics processing, such as thermoforming, hot-stamping and extrusion,” says project manager Ralph Jänchen. “Here, temperature sensors close to the surface can help to ensure reliable forming and high surface quality in these applications. Furthermore, the protective and non-stick coatings, which should be developed in the project, will also be usable for classic sealing and forming tools without sensors.”The project, which is financed by Germany’s BMWi (Federal Ministry for Economic Affairs and Energy), follows on from the HePhaiSt-Os project, which terminated in 2018. HePhaiSt-Os (‘New temperature sensors for heat-sealing’), which also ran under the auspices of the BMWi, culminated in the development and construction of a prototype heat-seal tool comprising two heating elements, each with eight measurement points, as well as the associated acquisition and evaluation hardware and software.

www.ivlv.org/en/project/robinpro/